In table lamp design and production, the base is often seen merely as a supporting structure. However, from a quality assurance perspective, it is far more significant. A well-made base not only bears the weight of the lamp body but also influences aesthetics and long-term durability.

Common base materials include metals (iron, brass, stainless steel), glass, ceramics, and natural stone. Each requires specific processing techniques and surface treatments. To guarantee quality before shipment, the base undergoes a strict inspection process:

Appearance Check – Detecting scratches, paint peeling, or color inconsistencies, especially important for high-gloss or electroplated finishes.

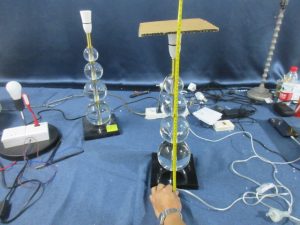

Structural Stability – Ensuring the base stands firmly without tilting or wobbling, reducing tipping risks during use.

Sample Consistency – Verifying that mass production matches the signed sample in texture, finish, and overall material quality.

Precise Measurements – Checking the diameter, height, and fit between the base, lamp pole, and lampshade to ensure seamless assembly and visual balance.

These meticulous checks ensure that every table lamp base meets safety and design standards, delivering a product that combines durability with style.