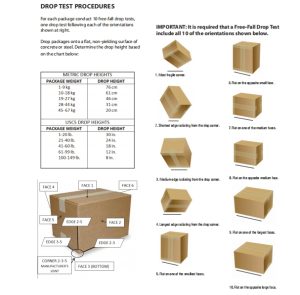

To ensure the durability of our table lamps and floor lamps during transportation and everyday handling, we conduct a rigorous drop test during inspection. This test simulates potential impacts during shipping or handling, checking the product and its packaging for sufficient shock resistance, so customers receive products in perfect working condition.

The drop height is not determined simply by product type, but scientifically based on the weight of the packaged product. This approach aligns with common industry standards, such as ISTA or ASTM. The typical standards we follow are:

Notes:

Lightweight table lamps (≤9 kg) are usually tested at 76 cm.

Heavier floor lamps (often 9–18 kg or more) are tested at 61 cm or 46 cm.

Each product is tested in its fully packaged state to simulate real transportation scenarios

Weigh the package and determine the corresponding drop height based on its weight.

Sample Preparation

Select a representative table lamp or floor lamp sample, ensuring it is fully packaged with all accessories included. Weigh the package and determine the corresponding drop height based on its weight.

Test Environment

Use a hard, flat surface such as concrete or a thick wooden platform.

Keep the area clean and ensure operator safety.

Drop Testing

Perform drops from the specified height in multiple orientations — front, side, and corner — to fully evaluate impact resistance.

Record the product condition and take photos after each drop.

Inspection and Evaluation

Check that the structure is intact, with no cracks, loose parts, or breakage.

Verify that all electrical components function properly (power on, switch operation, lighting).

Confirm that the packaging effectively protects the product.

Feedback and Improvement

If any damage, malfunction, or insufficient packaging protection is observed, product design or packaging will be improved accordingly.

Ensure accurate weighing of the sample to select the correct drop height.

Avoid any human interference during the drop to maintain test authenticity.

For fragile shades or decorative components, evaluate whether enhanced packaging is required.

Test personnel should wear protective gear to prevent injury.

Keep detailed records of test results for analysis and future improvement.

Through strict drop testing, we guarantee that every table lamp and floor lamp we deliver not only looks beautiful and works reliably, but also withstands the rigors of transportation and handling — ensuring peace of mind for your business and your customers.