While aging tests may seem simple, the effectiveness lies in the execution. Here’s how we carry out aging tests in real production and pre-shipment stages.

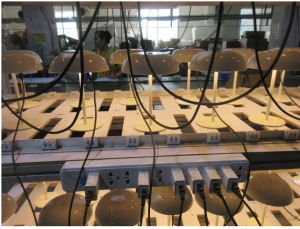

Aging racks or conveyor lines

Adjustable AC power supply (for voltage fluctuation simulation)

Ambient temperature control (optional)

Time tracking and monitoring system

1: Mount the LED lamps securely on the aging rack.

2: Power them on under rated voltage. Common test durations:

Table/Floor Lamps: ≥ 2 hours

Ceiling/Downlights: ≥ 4 hours

3: Observe during operation:

Is brightness stable?

Any flickering, dead LEDs, or color shift?

Abnormal heat, noise, or odor?

4: Recheck the lamps after aging to ensure no deformation or functional faults.

Common Issues & Fixes

| Issue | Possible Cause | Suggested Action |

|---|---|---|

| Flickering | Poor driver quality | Replace with better drivers |

| Partial outage | Faulty soldering/LEDs | Rework or replace LED beads |

| Odor/discoloration | Inadequate heat design | Improve thermal structure |